Universal control valve baelz 342-B

Universal control valve for industrial applications. Angle way Kvso = 2% (class I).

| Fluid | Nominal pressure | Nominal diameter | Body material | Temperature range |

|---|---|---|---|---|

| water / hot water | PN 16 – 25 | DN 15 – 125 | spheroid ductile iron (5.3103) | -10°C to 240°C |

Universal control valve baelz 342-BK and baelz 342-BK-SS

Universal control valve with cooling tube for industrial applications.

Type baelz 342-BK-SS additionally with stainless steel bellows, for applications using thermal oil.

Angle way Kvso = 2% (class I).

| Fluid | Nominal pressure | Nominal diameter | Body material | Temperature range |

|---|---|---|---|---|

| water / hot water;

thermal oil |

PN 16 / 40 | DN 15 – 125 | spheroid ductile iron (5.3103) /

cast steel (1.0619) |

-10°C to 350°C |

Universal control valve baelz 347-B and baelz 347-BB

Universal control valve for industrial applications. Straight way and angle way Kvso = 0,004% (better than class IV). Perfect suited to complex control solutions.

| Fluid | Nominal pressure | Nominal diameter | Body material | Temperature range |

|---|---|---|---|---|

| water / hot water

|

PN 16 – 25 | DN 15 – 300 | spheroid ductile iron (5.3103) | -10°C to 240°C |

Universal control valve baelz 347-BK and baelz 347-BK-SS

Universal control valve with cooling tube for industrial applications.

Type baelz 347-BK-SS additionally with stainless steel bellows, for applications using thermal oil.

Straight way and angle way Kvso = 0,004% (better than class IV).

| Fluid | Nominal pressure | Nominal diameter | Body material | Temperature range |

|---|---|---|---|---|

| water / hot water;

thermal oil |

PN 16 / 40 | DN 15 – 300 | spheroid ductile iron (5.3103) /

cast steel (1.0619) |

-10°C to 350°C |

Balanced universal control valve baelz 347-B-EMF

Balanced universal control valve for industrial applications with relatively constant operating conditions. Straight way and angle way Kvso = 0,004% (better than class IV).

| Fluid | Nominal pressure | Nominal diameter | Body material | Temperature range |

|---|---|---|---|---|

| water / hot water | PN 16 – 25 / 40 | DN 15 – 300 | spheroid ductile iron (5.3103) /

cast steel (1.0619) |

-10°C to 240°C |

Balanced universal control valve baelz 347-BK-EMF

Balanced universal control valve with cooling tube for industrial applications with relatively constant operating conditions. Straight way and angle way Kvso = 0,004% (better than class IV).

| Fluid | Nominal pressure | Nominal diameter | Body material | Temperature range |

|---|---|---|---|---|

| water, hot water | PN 16 – 25 / 40 | DN 15 – 300 | spheroid ductile iron (5.3103) /

cast steel (1.0619) |

-10°C to 315°C |

ANSI control valve baelz 367

Flanged control valve with pressure ratings according to American ANSI/ASME standards.

| Fluid | Nominal pressure | Nominal diameter | Body material | Temperature range |

|---|---|---|---|---|

| hot water / cold water,

glycol (up to 50%), thermal oil |

ANSI 300 | DN 15 – 250 (1/2″ – 10″) |

cast steel (SA216WCB) | -29°C to 343°C (-20°F to 650°F) |

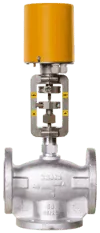

In constant flow applications, the bi-directional ports of a 3-way control valve allow water to bypass the coil or load through mixing or diverting. An actuator is used to force an upward and downward movement of the valve’s plug which works to open and close off the different ports to redirect pressure and flow. Mixing applications have two inlets and one outlet, while diverting applications move water through one inlet and two outlets. The three-way valve is more cost effective control option for diverting or mixing applications than the use of multiple 2-way valves.

How It Works: 3-Way Valves

How It Works: 3-Way Valves

- 3 main components: Valve body, Actuator, Spindle and Plug

- You can use pneumatic or electric actuation

- Available in many different diameters (15mm – 300mm)

- Different size actuators are available for different size valve bodies.

- There are three ports: A, B and AB

- Ports are bidirectional

- Tight seal leakage protection

These valves operate using an actuator which moves the valve plug up and down; this plug opens and closes the valve’s ports to help redirect the pressure and flow of the passing fluid.

As mentioned earlier, 3-way valves can be used solely for opening or closing a passage, or for modulating and precisely controlling the flow and temperature of the process. In comparison to 2-way valves are a most cost-effective choice for diverting and mixing applications.

Three Way Control Valves Ebook

This technical ebook provides a technical description of how Baelz 3-Way valves can be used as mixing or diverting valves, as well as the advantages that come with utilizing the Baelz 3-way valve.

3-Way Mixing Valves vs. 3-way Diverting Valves

Based on desired function, 3-way valves can be installed either as mixing or diverting valves. While a mixing valve has two inlets (A and B) and one outlet (AB), a diverting valve has one inlet (AB) and two outlets (A and B).

In diverting valves, the plug closes against the seat. Diverting valves should be used with low differential pressures and electric actuators rather than pneumatic. However, diverting valves can only be used in applications with low differential pressure, and can should be sued in with electric actuators- rather than pneumatic ones – as large drops in pressure may cause hammering of the plus. For these reasons, installing 3-way-valves as mixing valves is simpler and easier than installing them as diverting valves.

Applications of 3-Way Control Valves

Three-way control valves, also called multi-port valves, mixing valves, or simply three-way valves, can be used with many types of process fluids, including steam, gases, water, oil, and other liquids. Their three bidirectional ports that can be used to efficiently mix, separate, or control the flow of fluids in these ways:

- Diverting fluids to different process systems (in configurations with one inlet port and two outlet ports)

- Changing flow direction

- Changing or modulating the speed, flow rate, pressure, or temperature of the fluids

- Mixing fluids (in configurations with two inlet ports and one outlet port)

Three-way control valves from Baelz NA are available in both cast iron and steel materials and with port diameters from 15mm to 300mm. They are designed to work with fluids in a range of temperatures and pressures, and have tight seals to prevent leaks.

Some common applications that use three-way valves include:

HVAC Systems

Three-way valves control the inflow and mixing of hot and cold water to modulate temperatures inside the unit. This prevents overheating, excessive wear, and inconsistent temperatures.

Water Purification Systems

Water purification systems require dynamic controls to treat the water appropriately based on current water conditions. Three-way valves simplify the process of adding disinfectants and other chemicals that enter the system at each stage.

Hydraulic Systems

Three-way valves can be used to control hydraulic fluids like oil, and change the pressure, flow, or volume needed to operate the system.

Pneumatic Systems

Three-way valves can direct and control the flow of compressed air to actuators, valves, and in-use equipment units.

Chemical Processing

In chemical processing systems, three-way control valves are used to divert fluids to two separate parts of a system or to mix two fluids into a single outflow. Actuating devices that control the position of the plug make it possible to fine-tune the flow, pressure, or temperature.

Process Control

Three-way control valves can manage flow, pressure, and direction for fluids in virtually any industrial process.

Advantages of 3-Way Control Valves

Three-way control valves from Baelz NA are built for long-term use in general operations or in very specific applications. Our hardware offers the following advantages:

Versatility

The same three-way control valve design can be used for mixing, diverting, and fluid control operations. They can also be used for liquids and gases of various temperatures, pressures, volumes, and viscosities.

Cost and Space Savings

Three-way valves can provide the same functionality as multiple two-way valves. This makes it possible to streamline pipeline and process fluid systems with less equipment to install and maintain, and an overall smaller footprint.

Control Simplification

Three-way control valves simplify the steps involved in working with process fluids. Actuators and automated control systems can be programmed to toggle settings, manage flow control, and keep fluid moving the right way for every use case.

Simplified Design

Switching from multiple two-way ports to a three-way control port simplifies system design and makes it easier to control the movement of fluids in a pipeline. Fewer valves also means less maintenance, repair, or replacement over time.

Flexibility Over Flow Control

For systems that require more than simple on/off flow control, a three-way control valve makes it possible to mix, divert, or adjust fluids and flow characteristics as system needs change.

3-Way Control Valve FAQs

If you’re considering incorporating three-way control valves into your systems, it’s important to know how to select the right products and keep them in good condition.

How Do I Select the Right 3-Way Valve for My Application?

Most three-way control valves are designed in a T shape with three ports configured for two inputs and one output (i.e., mixing) or one input and two outputs (i.e., diverting). Beyond this basic design, there are several factors to consider when selecting a 3-way valve for your application, such as:

- Fluid: Consider the fluid type, pH level, pressure, temperature, and flow rate. These will determine the right materials and wall thickness for the valve. Whether the fluid is corrosive is also important in choosing between cast iron, steel, or other materials.

- Existing Piping: Measure your current pipeline size and available space so you can select valves that can physically fit into the system. Our 3-way valves are available in 15mm to 300mm diameters.

- Actuation Requirements: Manual, electrical, or pneumatic actuators are available to move the plug and control fluid flow.

- Safety: Consider the minimum and maximum temperatures and pressure levels in the system so valves can be sized correctly and made from suitable materials.

How Should 3-Way Valves Be Maintained?

Three-way control valves are low-maintenance and do not require constant monitoring, lubrication, or other modifications. Like all of the hardware in a fluid system, they should be inspected regularly for signs of leaks, damage, and debris buildup.

Contact Baelz NA for 3-Way Control Valves

As the official distributor of Baelz Automatic actuators, controllers, and valves, Baelz North America is proud to offer top-quality 3-way control valves. Curious to learn more about the benefits and uses of 3-way valves, or need to discuss your application with an expert? Contact us today.

Looking for Technical Data and Resources?

Browse our collection of eBooks, brochures, and data sheets.

Get access now!

Please complete the form below to access the data sheets on this page. Click here to return home.

How It Works: 3-Way Valves

How It Works: 3-Way Valves