Ejectors can be used wherever the main pump generates sufficient differential pressure. According to VDI 2067, conventional circulation pumps have a lifetime of 10 years, whereas ejectors have a lifetime of 20 years. Ejectors are frequently used in the energy sector, in heating, hot water, and ventilation system applications. Baelz ejectors can be utilized with pneumatic or electric actuator options.

What Is an Ejector?

Ejectors are static devices that use the high pressure of a motive liquid or gas to compress and entrain a low-pressure flare gas to an intermediate discharge pressure. Ejectors are mounted to the pipeline and can be produced from various materials to suit different process conditions.

Ejectors are an energy-efficient process solution that ensures an efficient flow of energy through heat transfer fluids. Ejectors will provide distribution and the exact amount of heated water over dozens of circuits without the use of a pump. Based on Bernoulli’s equation and the Venturi principle, the kinetic energy of water is conserved and not wasted like a typical 3-way valve application.

Ejectors Available From Baelz NA

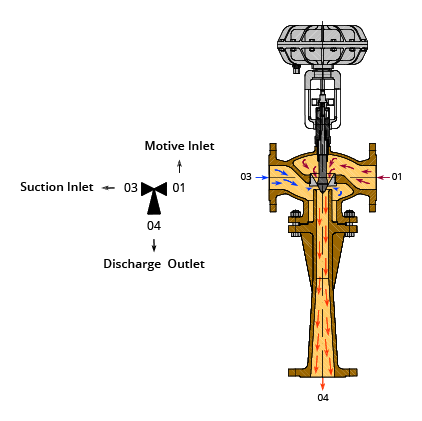

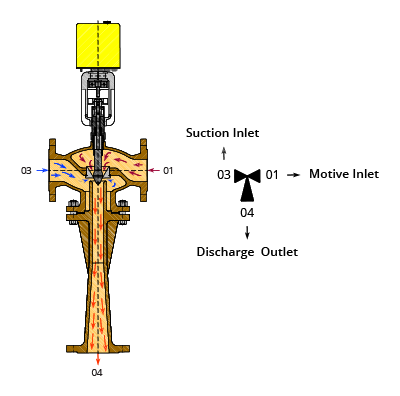

Baelz NA offers controllable nozzle water and steam ejectors. A controllable nozzle ejector is a 3-way control valve with intrinsic suction power. These ejectors have a motive inlet, suction inlet, and discharge outlet on the bottom.

Steam Ejectors

Steam jet ejectors are the largest-sized vacuum-producing ejectors currently available for highly demanding applications. The ejectors contain few moving parts, making them nearly maintenance-free. Baelz NA fabricates steam jet ejectors from various materials for use in any industry that requires vacuum pressure.

Baelz Jetomat® steam ejectors rely on similar components and operating principles as traditional controllable ejectors, reducing energy consumption and delivering reliable performance. Our selection of Jetomat® ejectors can mix steam and water directly for applications such as:

- Water heating

- Saturated steam conditioning

- Condensate reuse

- Superheated steam cooling

- Recirculation ejectors

Water Ejectors

To distribute heating water to secondary circuits, Baelz Jetomat® water ejectors use controlled ejector technology in place of pumps and control valves for each circuit. Using our ejectors can deliver long-term cost and energy savings in ventilation and heating systems, with many systems operating for 30 years or more. Our water ejectors can replace any water control valve in systems where the main pump generates adequate differential pressure.

How Do Ejectors Work?

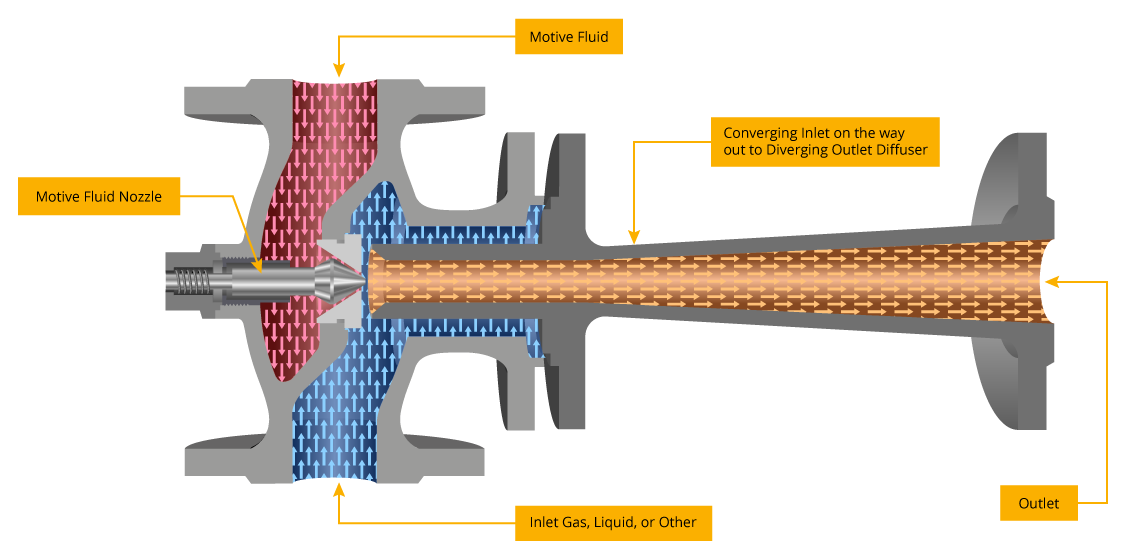

Ejectors work on Bernoulli’s principle, which states that fluid velocity increases as pressure decreases. The opposite is also true—as fluid velocity decreases, its pressure increases. Ejectors accelerate a motive, or high-pressure stream, through the nozzle, generating velocity from the motive’s pressure. They create the highest velocity around the nozzle tip, resulting in a low-pressure region called the ejector’s suction chamber.

The region where the pressure is lower than that of the suction fluid connects to the ejector’s suction branch or side inlet. The suction branch carries the fluid into the ejector body, transferring the two fluid streams through the ejector’s diffuser, where they decrease in velocity and increase in pressure due to the diverging geometry. As the suction stream pressure compresses and increases, the pressure of the motive stream decreases, transferring a portion of its energy to the suction stream. As a result, the pressure that the ejector discharges falls between the motive and suction pressures.

Source Ejectors From Baelz NA

Ejectors are simple devices mounted to fluid system pipelines that compress and transport suction fluid in motive fluid systems. They are an energy-efficient, low-maintenance solution with few moving parts, minimizing maintenance needs. Their efficient operation and longevity can result in a significantly lower cost of ownership over the device’s lifespan compared to circulation pumps.

Baelz NA produces and supplies various ejectors, including steam ejectors and water ejectors. Our Jetomat® steam ejectors can be used to cool superheated steam, heat water, reuse condensate, and condition saturated steam. Our water ejectors can replace pumps and control valves in secondary circuit systems, reducing energy consumption. Contact us or request a quote to speak with a specialist about the ejector solution for your application.

Looking for Technical Data and Resources?

Browse our collection of eBooks, brochures, and data sheets.

Get access now!

Please complete the form below to access the data sheets on this page. Click here to return home.