Control Valves for Thermal Fluid Systems

As critical components of many industrial applications, control valves regulate fluid pressure, flow level, direction, and temperature in many types of fluid handling applications. Baelz manufactures a large selection of high-quality 2-way and 3-way control valves. One of the most common applications of these valves is in a thermal fluid system’s secondary loop.

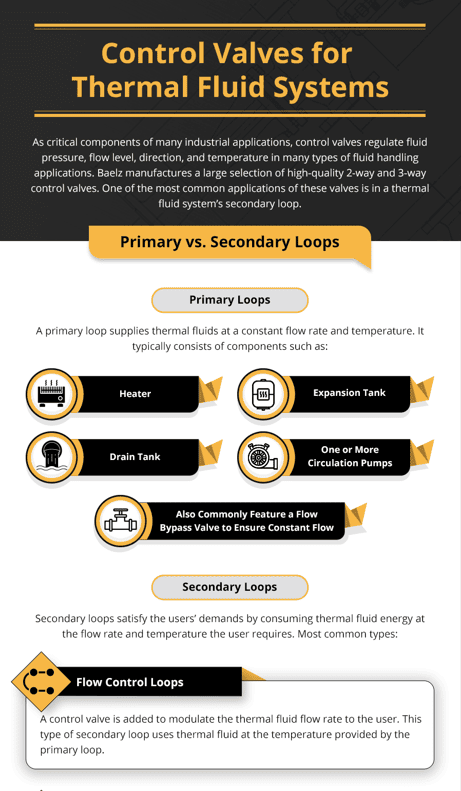

Primary vs. Secondary Loops

In thermal heating systems, a primary loop supplies thermal fluids at a constant flow rate and temperature. It typically consists of components such as a heater, expansion tank, drain tank, and one or more circulation pumps. Primary loops also commonly feature a flow bypass valve to ensure constant flow to the heater while the users are modulating.

Secondary loops satisfy the users’ demands by consuming thermal fluid energy at the flow rate and temperature the user requires. Flow control loops and temperature control loops are the two most common types of secondary loops.

Types of Secondary Loops

Within a thermal fluid system, there are two primary mechanisms for controlling a user’s heat energy supply: flow control loops and temperature control loops. In flow control loops, a control valve is added to modulate the thermal fluid flow rate to the user. This type of secondary loop uses thermal fluid at the temperature provided by the primary loop.

In contrast, a temperature control loop offers the ability to measure and control thermal fluid temperature through the user. This type of secondary loop receives thermal fluid at temperatures above the desired loop temperature and uses a pump and control valve to regulate the secondary loop to a temperature below the primary loop temperature. In some applications, flow control loops are used within temperature control loops; however, they can also be used parallel to each other within the same system.

Two-Way vs. Three-Way Valves

Whether you’re directly controlling flow to a high-temperature user from the primary loop or using a secondary loop to regulate temperature, you will always need a thermal fluid control valve. Selecting the most suitable option involves choosing between two-way and three-way valves. While both configurations will work, they each have distinct advantages and disadvantages to consider.

Two-Way Valve Considerations

Two-way valves are most suitable for applications that don’t require constant energy in a second loop or user and instead leave the energy available for other secondary loops. One example of this is batch loading in chemical reactors. This type of user doesn’t have a consistent heat demand, making two-way valves a suitable solution.

When multiple reactors only run periodically, the heater only needs to accommodate the maximum number of reactors running simultaneously. Using two-way valves at each reactor diverts flow to the equipment being actively heated. Two-way valves that control flow to users require an additional two-way valve to act as an automated system bypass for maintaining constant flow in the heater.

Three-Way Valve Considerations

Three-way valves are most commonly used in applications that permit a fixed flow through the valve whether energy is being consumed by a secondary loop or not. Looking at the example of batch chemical reactors again, three-way valves would require the heater to be able to accommodate every reactor in the system, not only the ones that are operating.

Three-way valves are also a good selection for single-user or multi-user systems that are sized for all users operating together. In these applications, a three-way valve can operate as a diverting valve or a mixing valve. A diverting valve features one inlet and two outlets and is typically installed upstream. A mixing valve, on the other hand, features two inlets and one outlet and is installed downstream of the user.

2-Way and 3-Way Control Valves for Thermal Fluid Systems

Thermal fluid systems require reliable 2-way and 3-way control valves to protect end users and keep operations running smoothly. Products from Baelz are factory-tested to verify industry compliance and deliver high performance under even the most challenging conditions. You can learn more about our control valve product offerings here, or you can contact us with any questions. To get started on your thermal fluid system solution, request a quote today.