Desuperheater Applications

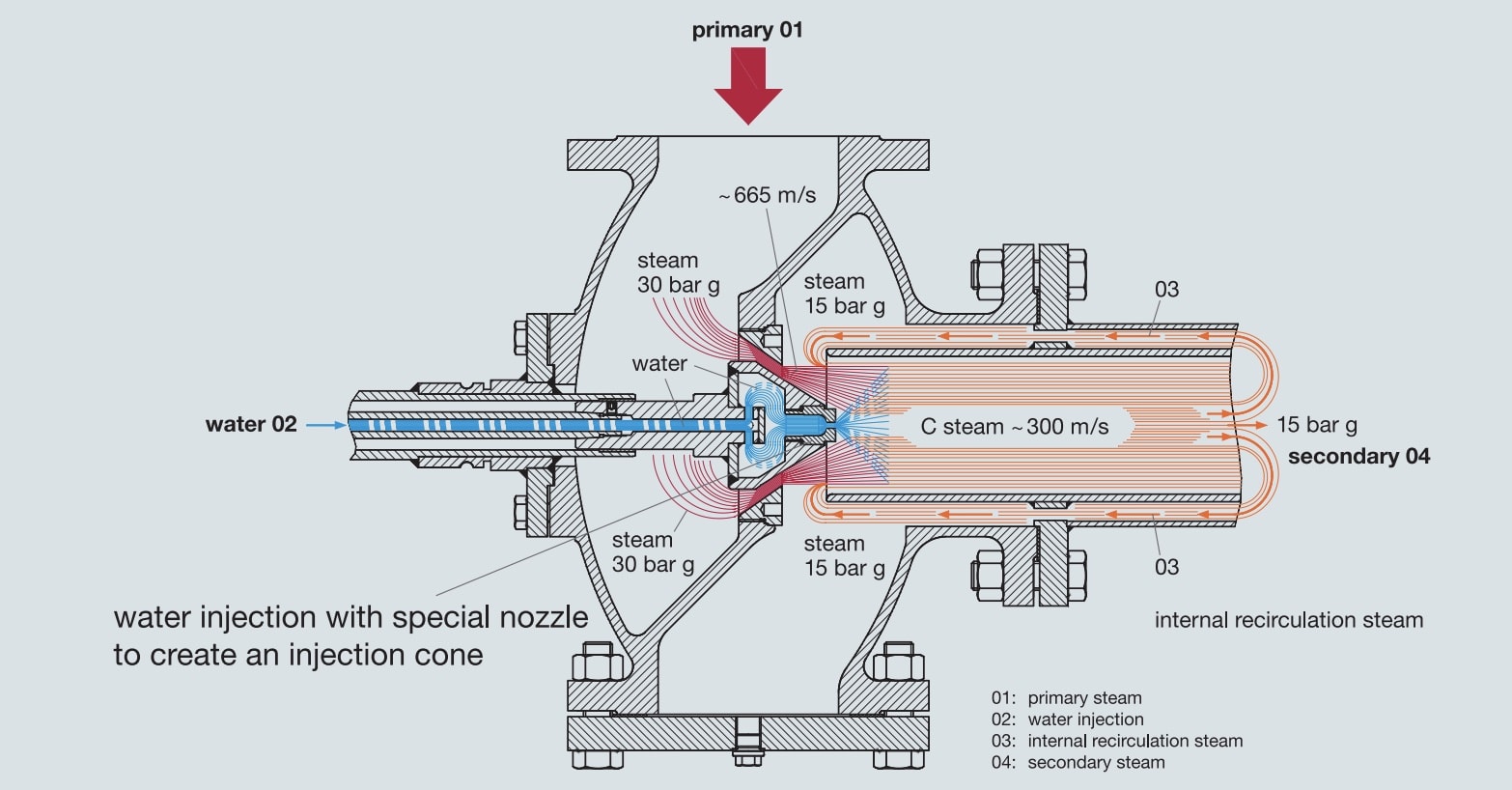

Desuperheaters reduce the temperature of dry, superheated steam as it enters equipment by injecting a precise quantity of water into the steam flows. The resulting saturated steam aids in industrial heat transfer applications. Superheated steam reaches temperatures in excess of 212° F, and desuperheaters help control and maintain steam temperature to prevent downstream equipment damage and improve operations and product quality.

Doing this properly means matching the desuperheater equipment to your unique steam system’s temperature, pressure, and flow dynamics. At Baelz North America, our expert team helps clients in multiple industries address their desuperheater needs. The power generation and process industries are two markets we serve that depend on desuperheaters to optimize heat transfer and manage steam safely and effectively.

Power Generation

Lowering the pressure and temperature of superheated steam, such as from a power boiler’s turbine bypass system, is essential to maintain stable and precise heat transfer. The steam that exits the boiler is high-pressure, superheated steam, with the capability of supplying thermal energy to other components and systems within a power generation plant. Desuperheaters will help you achieve an efficient temperature setting, providing the saturated steam that will aid in effective and safe heat transfer in facilities like power, petrochemical, and refinery plants.

Process Industry

The process industry also utilizes process steam and heat exchanger solutions, of which a desuperheater is one. Like in the power generation industry, desuperheaters in this sector lower steam pressure and temperature as the steam comes out of boilers, giving processing plants the ability to control these two factors. Conditioning the raw steam makes it more economically viable for process operations. Once it approaches near saturation, it carries out heat transfer more effectively. Ultimately, desuperheaters allow process plants to run reliably with a reduced risk of downtime, boosting productivity and profitability. Examples of the process industry include chemical, petroleum, wood, and food processing operations.

What Are the Advantages of Desuperheated Steam?

Desuperheaters lend numerous advantages to operations that generate superheated steam. This equipment and the desuperheated steam they create are beneficial for:

- Accurately controlling temperature

- Allowing for higher-quality industrial operations and goods

- Reducing costs through greater heat conservation and reuse

- Safeguarding against heat damage in downstream equipment

- Decreasing the risk of unplanned system downtime

- Enabling longer equipment service life

- Producing lower volumes of steam

- Lowering system requirements (e.g., lighter flanges, narrower pipes, and lower metal alloy grades)

- Enhancing efficiency in chemical processing and power generation, as well as downstream heat exchangers

Find the Desuperheater for Your Application

Thermal regulation and efficient energy transfer are two of the most effective ways to optimize industrial system performance and reduce energy waste. In the power generation and process industries, a desuperheater effectively offsets energy costs and maximizes system availability to safeguard against downtime.

For well over a century, Baelz has provided innovative, energy-saving systems and components that offer lasting, dependable solutions for process heating and cooling control. We serve industries ranging from automotive and marine to chemical and wastewater. By emphasizing designs with fewer system components, we optimize system reliability and cost-effectiveness.

To learn more about desuperheater applications and how to control your steam systems for greater performance and reduced energy consumption, contact us or request a quote today.