Our 2-way valves feature a simple design that allows customers to reduce their operating and energy costs. While they are ideal for use in simple on/off applications, they are also suitable for managing conditions in variable flow systems with changing pressures. These valves accommodate use with hot and cold oil, water, and steam. Various sizes are available.

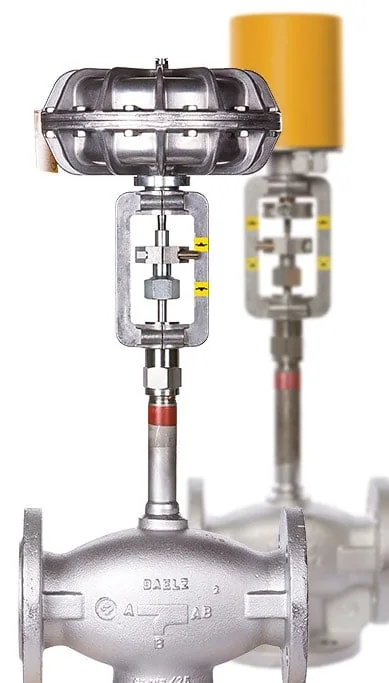

Our 3-way valves can be configured as mixing or diverting valves. In mixing applications, two openings are designated as inlets and one as an outlet, whereas in diverting applications, two openings serve as outlets to a single inlet. These valves are easily converted into 2-way valves by capping the “B” port. They are designed and built for excellent leakage protection with a stainless steel spindle and plug for maximum durability.

Both of these valve types feature three main components: a valve body, an electric or pneumatic actuator, and a spindle or plug. They are available in several variations to suit different fluid media (e.g., water, steam, oil, etc.) and fluid conditions (e.g., flow rate, pressure, temperature, etc.), all of which are designed and constructed for durability and reliability. For example, our stainless steel bellows can withstand temperatures up to 350° C (662° F) for over 120,000 up and down reps.

Baelz North America is a manufacturer of a large selection of high-quality control components and systems. One of our core product offerings is control valves, which are available in two-way and three-way models with electrical and pneumatic operation.

Valves are mechanical or electromechanical devices designed to regulate and/or redirect the flow of fluids through process heating systems by partially or completely blocking flow passages. This function is critical to the success of a wide range of industrial applications. For this reason, they are available in many variations, each of which may differ in regard to design, construction, and size. In the industrial sector, one of the most commonly employed types of valves is the control valve.

Industrial control valves work by selectively opening and closing passages to control fluid flow level, direction, pressure, and temperature. As such, they help facility workers maintain consistent conditions throughout an operation, resulting in better product and process quality.

-

Advantages of Control Valves

When selected, installed, and maintained properly, control valves benefit processing facilities in several ways, including in regard to the following:

Process Consistency

Control valves help system operators ensure operating conditions remain within the acceptable range, resulting in better process consistency throughout an operation and between operations.

Product Quality

Consistency and quality go hand-in-hand. Variability in processing operations inevitably leads to products of varying quality. By using control valves—which enable better process consistency — processing facilities minimize the risk of variation between products and product batches, resulting in better overall product quality.

Production Efficiency

Reduced process variability also translates to less material waste, as fewer substandard products will need to be scrapped. Additionally, the greater precision offered by control valves results in less time spent making adjustments to the process throughout an operation.

Energy Efficiency

Many processing operations require specific operating temperatures, pressures, and other flow conditions. Control valves help equipment maintain the desired conditions throughout the process, reducing the amount of energy needed for optimal processing performance.

All of the above advantages add up to substantial cost savings, which can significantly impact the profitability of a manufacturing or processing facility. However, experiencing these benefits necessitates the proper selection, installation, and maintenance of the control valve employed.

-

The Importance of Proper Maintenance & Repair for Control Valves

Control valves play a critical role in fluid handling and processing systems. However, even if the right control valve is installed in a system, it will not function as intended without proper maintenance throughout its service life.

-

Industrial Applications of Control Valves

Control valves find application in the fluid handling and processing equipment of a wide range of industries, including the following:

Chemical

Due to the often hazardous nature of the chemicals employed, processing facilities in the chemical industry require precise control over fluids. Control valves allow facility workers to maintain appropriate pressure, temperature, and flow levels during operations, including for abrasive, acidic, corrosive, and other chemicals.

Food and beverage processing

In food and beverage processing operations, control valves (and other equipment components) must comply with strict sanitation standards. They are used to control the flow of materials ranging from steam and water to slurry and mash.

Marine

In the marine industry, control valves are used for precise liquid flow regulation and control to ensure systems maintain optimal operating conditions.

Power generation and distribution

Control valves are found in a wide range of power plant equipment and systems, including boilers, blowers, heat exchangers, and turbines.

Water and wastewater treatment

In water and wastewater treatment facilities, control valves regulate water flow and pressure. In particular, they are often employed in boiler systems to control the feeding and discharge of treated water and negate the effects of corrosion and scaling.

Wood

Control valves are used in wood drying and pressing operations to mix or divert thermal fluid flow, depending on how much moisture is present in the raw wood material.

Contact the Valve Experts at Baelz North America for Control Valves

Control valves serve a key role in many different industrial equipment and systems. For this reason, it is essential to source quality control valves from a reputable supplier to ensure the components function as intended. If you need high-performance control valves, turn to the experts at Baelz NA.

MTR/CRN CertifiedComply with American and Canadian requirements for ANSI and DIN standards

Confident in Your InvestmentAll of our valves are factory tested to verify they are industry compliant

For additional information about our control valves and other control components or assistance choosing one for your needs.

Contact Our Team TodayGet access now!

Please complete the form below to access the data sheets on this page. Click here to return home.