Baelz steam injectors offer many distinct advantages, including:

Jetomat® baelz 590

Steam/steam ejector with flanged connection for recirculation and compression of exhaust vapor.

| Fluid | Nominal pressure | Nominal diameter | Body material | Temperature range |

|---|---|---|---|---|

| steam | PN 16 / 40 | DN 15 – 250 | spheroid ductile iron (5.3103) / cast steel (1.0619) |

-10°C to 240°C (without cooling tube) -10°C to 350°C |

Baelz-Jetomat® Steam Ejectors

Baelz-Jetomat® steam ejectors use the same basic components and principles as controllable ejectors to ensure reliable performance and reduced energy costs. Our available models can directly mix steam with water for water heating applications, or condensate reuse, condition saturated steam, or serve as a desuperheater for superheated steam cooling.

Applications

Baelz-Jetomat steam ejectors can be installed in either recirculation or condensate reuse for efficient performance.

Applications

Baelz-Jetomat steam ejectors can be installed in either recirculation or condensate reuse for efficient performance.

-

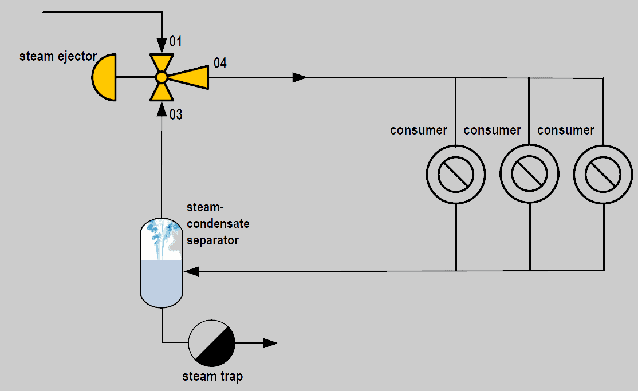

Recirculation Systems

Recirculation systems are built to increase the performance and efficiency of your machines. Not only can they increase thermal performance by up to 15%, but they can also save up to 5% steam consumption.

-

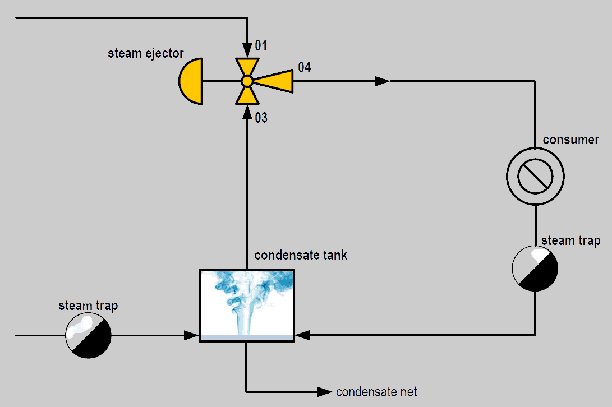

Compression Systems

Compression systems save energy, often achieving steam savings between 10% and 30% or mo.

Steam ejectors are typically used in the following commercial and industrial applications:

- Petrochemical Processes

- Thermal Compressors

- Oil Distillation and Deodorization

- Fertilizer Plant Operations

- Drum Dryers (textile and paper mills)

- Bakery Ovens

Advantages at a Glance

- Energy Savings. Because our steam ejectors reduce the amount of steam loss, the system requires less energy overall to maintain consistent performance.

- Cost Savings. Reduced energy consumption automatically reduces operating costs.

- Improved Machine Performance. Because of the superior vacuuming technology, ejectors can work with high pressures and pressures as low as 3 microns HgA. They are also capable of increasing the effective heating surface to 100%.

- Flexibility/Cross-Compatibility. Steam ejectors are versatile equipment and are applicable in all types of steam systems.

- Easy Installation/Use. System technicians can easily install steam ejectors because they are lightweight and don’t need foundations.

- Corrosion and Erosion Resistance. Steam ejectors can be constructed from a variety of materials, including corrosion-resistant materials. Steam ejectors can also be coated with corrosion-resistant layers that offer additional protection.

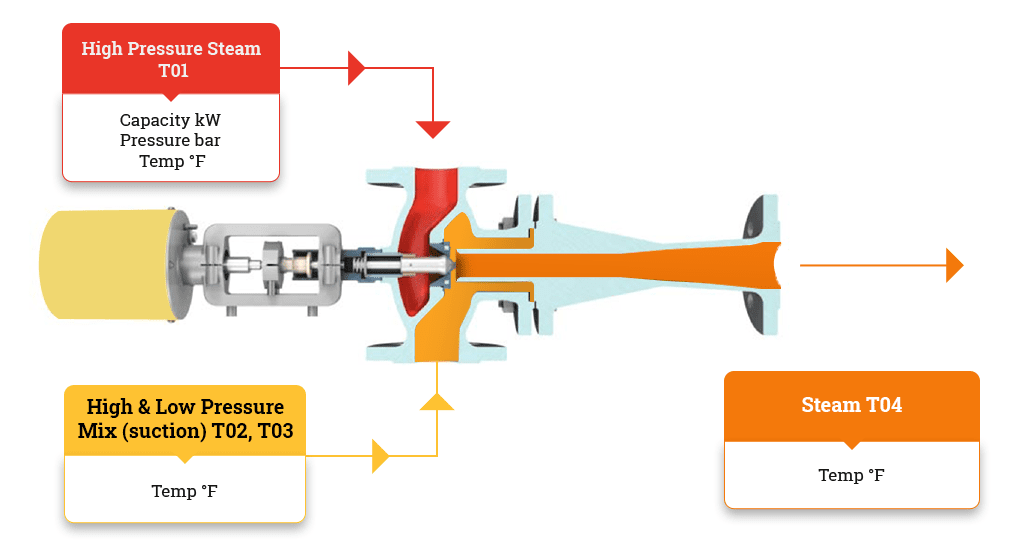

System Components

Motive Chest

Suction Chamber

Motive Nozzle

Diffuser

Pneumatic or Electric Actuator

Special Steam Ejection Plug

Looking for Technical Data and Resources?

Browse our collection of eBooks, brochures, and data sheets.

Get access now!

Please complete the form below to access the data sheets on this page. Click here to return home.