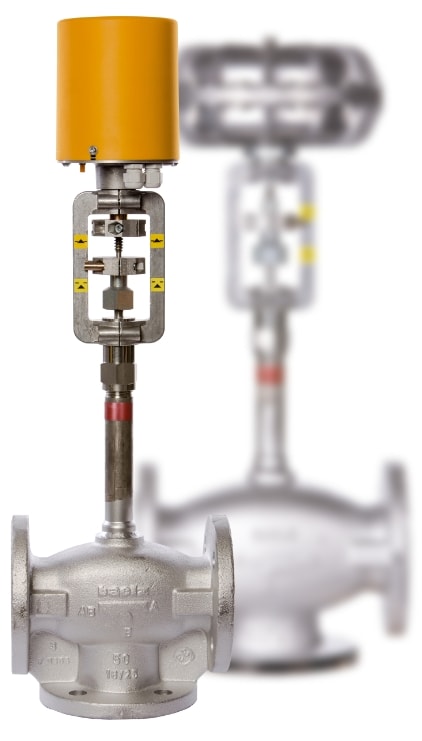

Control Valves Applications

Two-way and three-way control valves are critical components of many industrial applications. Our high-quality control valves selectively open and close passages to control fluid direction, temperature, flow level, and pressure.

Thermal Fluid Systems

In the industrial sector, two-way and three-way valves are commonly employed in the secondary loop of a thermal system. The two primary mechanisms for controlling the heat energy supply within a thermal fluid system include temperature control loops and flow control loops.

In flow control loops, a control valve helps to modulate the thermal fluid flow rate. This type of secondary loop relies on thermal fluid at a set temperature provided by the primary loop.

In temperature control loops, the user can control and measure the thermal fluid temperature. This type of secondary loop receives thermal fluid at temperatures higher than the desired loop temperature, using a control valve and pump to regulate the secondary loop at a temperature lower than the primary loop temperature.

Control Valves in Steam Condensate Recovery Systems

Steam condensate recovery systems rely on control valves to open and close passageways to manage fluid flow level, pressure, direction, and temperature. These systems help reclaim the condensate formed during steam generation. The condensate can be reused for a variety of processes while providing the following benefits:

- Improved energy efficiency

- Reduced water treatment costs

- Lower fuel and water costs

Dryer Kilns

A kiln dries wood by lowering the moisture level of the material. In wood processing, control valves play a crucial role in the effective operation of the kiln.

Baelz NA valves can be employed as an urgent system bypass, with the proper control valves improving wood processing in ways that include:

- Increased efficiency

- Higher quality

- Higher levels of consistency

- Enhanced energy efficiency

Water Glycol Applications

Water glycol control valves are available in two-way and three-way configurations, with a valve body designed for heavy-duty operating environments.

The one-piece body includes a spindle, plug, and bellow seals to eliminate potential leak points. Glycol control valves can also be used in cooling and heating systems to control fluid flow and regulate equipment.

Common applications for water glycol control valves include the following:

- Water Chillers

- Process Heating & Cooling

- Food & Beverage

- Petroleum – Oil & Gas

- Chemical

- Power

District Heating & Cooling

District heating involves an underground infrastructure system where a central energy plant supplies thermal energy to various buildings and communities. It is a suitable cooling and heating alternative that eliminates the need for installing boilers in individual buildings.

The central plant provides a constant supply of hot water or steam, which travels through the underground insulated thermal piping network to transfer the thermal energy to the above-ground structures.

Heat distribution systems that rely on steam for thermal heat transfer utilize an underground piping network to transmit superheated steam. Baelz NA steam transfer stations offer space-saving solutions for a steam network via the Luxese Instant Heat system. Using the hydrodynamic jet pump technology from Baelz, water can be pumped to heat transfer stations, where it is heated to 180 °C (356 °F).

Our modular heat exchanger allows for impressive system availability and flexible design capabilities. The Module Baelz 147 is the most unique and universally recognized modular heat exchanger on the market.

Steam Ejector Applications

Steam ejectors ensure the efficient flow of energy in heat transfer fluids. Our ejector models can combine water with steam for a broad range of applications, including:

- Conditioning saturated steam

- Cooling superheated steam (replacing a desuperheater)

- Condensate reuse

- Water heating tasks

Jetomat® steam ejectors from Baelz NA provide excellent performance in condensate recirculation or reuse applications. In compression systems, the ejectors can significantly reduce steam consumption by 10-30% per month. In recirculation applications, steam ejectors can increase performance and efficiency, increasing thermal performance by up to 15% and reducing steam consumption by up to 5%.

Various applications and industries can benefit from steam jet ejectors. Some of the most common applications include but are not limited to the following:

- Drum dryers in textile and paper production

- Bakery ovens

- Fertilizer plant production

- Oil deodorization and distillation

- Petrochemical processes

- Thermal compressors

Desuperheater Applications

Desuperheaters are crucial in industrial settings, lowering the temperature of superheated steam entering equipment by injecting water, resulting in saturated steam for efficient heat transfer. Baelz North America specializes in tailoring desuperheaters for diverse industries, including power generation and process sectors. In power generation, desuperheaters stabilize heat transfer by reducing the pressure and temperature of superheated steam. Similarly, in the process industry, desuperheaters enhance control in various operations. Desuperheated steam provides advantages such as precise temperature control, improved operations, cost reduction through heat conservation, equipment damage prevention, downtime risk mitigation, extended service life, lower steam volumes, reduced system requirements, and enhanced efficiency in chemical processing and power generation.