Steam Condensate Recovery Systems

Steam condensate recovery systems work to reclaim the condensate that is formed during the steam generation process. This condensate can then be reused for various processes, providing benefits such as energy efficiency, lower water treatment costs, reduced water and fuel costs, and more. To ensure optimal performance, steam condensate recovery systems need quality components. At Baelz North America, we offer quality 2- and 3-way control valves to manage fluid flow within these systems.

Steam Condensate Recovery Systems Layout

There is no “one size fits all” solution when determining the best layout for condensate pipework. The ideal layout will depend on your application’s pressure, the pressure in the condensate return main, the stream trap properties, and the position of the condensate return main. To ensure you design a layout that meets your needs, it’s best to first consider what your system needs to achieve.

When designing the best layout, its important to keep the following objectives in mind:

- Condensate accumulation in the plant. Condensation should not accumulate in the plant unless the steam-utilizing equipment is designed to operate in that manner. In most cases, the equipment is designed for non-flooded operation, so when this is the case, accumulated condensate can negatively affect performance and cause corrosion to pipes, fittings, and equipment.

- Condensate accumulation in the steam main. Similarly, condensation should not accumulate in the steam main, as this can be picked up by high-velocity steam, resulting in water hammer and erosion in the pipework.

Types of Steam Condensate Recovery Systems

Within a condensate recovery system’s drain line, all non-condensable gasses should flow from the plant’s drain outlet to the steam trap. In properly sized drain lines, the plant and the body of the steam trap are at nearly equal pressures, causing the condensate not to flash in the line. Gravity is relied upon to facilitate flow within the pipe. Because of this, the trap should be positioned under the plant’s outlet and the trap discharge pipe should terminate under the trap.

The type of stream trap you choose can affect the piping layout. The three main types of steam traps include:

Thermostatic Steam Traps

This type of trap cools condensate below the saturation point prior to discharging. This waterlogs the drain line, causing the condensate to back up and flood the plant. With this type of steam trap, less flash steam generates in the trap discharge line, and the introduction of condensate into the condensate main is more smooth. Compared to mechanical traps, thermostatic stream traps with open-ended piping waste less energy by allowing processes to harness heat from the waterlogged condensate.

Thermodynamic Steam Traps

Thermodynamic steam traps discharge intermittently, accumulating condensate between discharges. However, they offer benefits such as a tolerance for freezing ambient temperatures, a small outer surface area to minimize ambient heat loss, and a robust design. These steam traps are not ideal for discharging condensate into flooded return lines.

Mechanical Steam Traps

Mechanical steam traps are often a popular choice due to their continuous discharge characteristics and ability to vent air. Mechanical float traps are typically available in two flow configurations: vertical flow or horizontal flow. Inverted bucket traps have top outlet and bottom inlet connections.

Steam Condensate Recovery System Components from Baelz

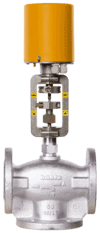

Control valves are important components of steam condensate recovery systems. These valves work to open and close passageways to manage fluid flow level, temperature, pressure, and direction. At Baelz North America, we offer the following industrial control valve products for steam condensate recovery:

2-Way Control Valves

Our 2-way control valves are suitable for cooling and heating water, hot oil, and steam applications. They feature an inlet and outlet port and are often used in basic on/off applications as well as variable flow systems that encounter changes in pressures, flows, and temperatures. Key benefits of our 2-way control valves include:

- High energy and cost savings

- Easy to install

- Ideal for control applications

- Suitable for on/off applications.

3-Way Control Valves

For constant flow applications, our 3-way control valves allow water to bypass the load or coil through diverting or mixing. An actuator forces the valve’s plug in an upward or downward movement to open or close off the ports to redirect flow and pressure. In a mixing valve, there is one outlet (AB) and two inlets (A and B). In a diverting valve, there are two outlets (A and B) and one inlet (AB).

Source Components for Steam Condensate Recovery from Baelz

Steam condensate recovery systems rely on quality components to ensure optimal performance. As a leader in providing a range of energy-saving components and engineered systems, Baelz North America offers quality 2- and 3-way valves for efficient steam condensate recovery. For more information about our steam condensate recovery system components, request a quote or contact us today.