Electric linear actuators convert rotational motion into straight line movements. They are known for their excellent repeatability and precision when operated in applications requiring specific valve positioning. They can be easily mounted on all DIN or ANSI valves and offer versatility with the following power supply option: 115V, 230V, or 24V. An electric motor turns the spindle up or down, which pushes or pulls the control valve spindle.

These actuators are manufactured for exceptional performance with low maintenance requirements. They may also be controlled digitally for exact valve positioning operations.

When a process requires emphasis on speed without compromising performance, pneumatic linear actuators are a good fit. These devices utilize compressed air to push or pull the spindle upward or downward as required by the valve’s position.

They are built with internal springs to set a desired fail open or fail closed positions in the event of outage. Internal springs come in different strengths tailored to meet pressure requirements. Pneumatic linear actuators are available in varying sizes to meet maximum stroke and operating pressures.

Actuators induce mechanical action by converting electrical, hydraulic, or pneumatic signals into motion. They are found across many industries in applications where precision valve control is needed. Electric linear actuators offer superior precision, while pneumatic linear actuators are essential to applications where speed, for the opening or closing of valves, is required. Such actuators may commonly be found in valve control applications across wood, automotive, food and beverage, chemical, and energy operations.

At Baelz NA, our electric and pneumatic actuators are engineered with precise or quick positioning support and feature a long service life, even in environments with high ambient temperatures or in harsh classified environments.

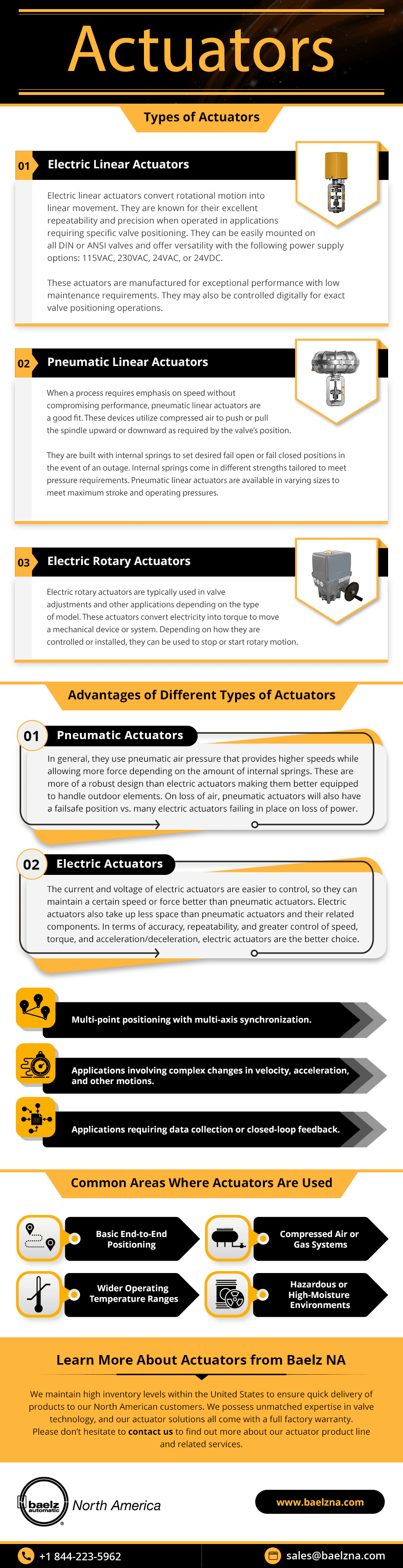

Types of Actuators

Electric Linear Actuators

Electric linear actuators convert rotational motion into straight-line movements. They are known for their excellent repeatability and precision when operated in applications requiring specific valve positioning. They can be easily mounted on all DIN or ANSI valves and offer versatility with the following power supply options: 115VAC, 230VAC, 24VAC, or 24VDC. An electric motor turns the spindle up or down, which pushes or pulls (extends/ retracts) the control valve spindle.

These actuators are manufactured for exceptional performance with low maintenance requirements. They may also be controlled digitally for exact valve positioning operations.

Pneumatic Linear Actuators

When a process requires emphasis on speed without compromising performance, pneumatic linear actuators are a good fit. These devices utilize compressed air to push or pull the spindle upward or downward as required by the valve’s position.

They are built with internal springs to set desired fail open or fail closed positions in the event of an outage. Internal springs come in different strengths tailored to meet pressure requirements. Pneumatic linear actuators are available in varying sizes to meet maximum stroke and operating pressures.

Electric Rotary Actuators

Electric rotary actuators are typically used in valve adjustments and other applications depending on the type of model. These actuators convert electricity into torque to move a mechanical device or system. Depending on how they are controlled or installed, they can be used to stop or start rotary motion.

Advantages of Different Types of Actuators

Choosing an actuator for a specific application depends on the characteristics of the job it needs to perform and where it will be installed. Compare the unique advantages of the different types of actuators:

- Pneumatic actuators: Pneumatic actuators are simpler in design and have much lower upfront purchasing costs. In general, they also provide higher speeds and lower forces than electric actuators, but this can vary depending on the number of pistons in the pneumatic actuator or the electric actuator’s screw pitch/lead.

- Electric actuators: The current and voltage of electric actuators are easier to control, so they can maintain a certain speed or force better than pneumatic actuators. Electric actuators also take up less space than pneumatic actuators and their related components. In terms of accuracy, repeatability, and greater control of speed, torque, and acceleration/deceleration, electric actuators are the better choice.

Applications of Different Types of Actuators

Specific physical and functional characteristics of the different types of actuators influence which is the best fit for an individual application. In general, pneumatic actuators are most often used for:

- Basic end-to-end positioning

- Compressed air or gas systems

- Wider operating temperature ranges (-20 to 350 °F)

- Hazardous or high-moisture environments

Electric actuators are more commonly utilized in applications such as:

- Multi-point positioning with multi-axis synchronization or advanced motion profiles

- Applications involving complex changes in velocity, acceleration, and other motions

- Applications requiring data collection or closed-loop feedback

Electric rotary actuators are used most frequently in liquid and gas piping systems where their ability to easily and effectively provide precise flow control is essential. They are commonly used in the energy, medical, and aerospace industries.

Actuator FAQs

Here are answers to some common questions we get about actuators:

Learn More About Actuators from Baelz NA

Baelz is dedicated to developing high-performance actuators for a comprehensive range of applications. Our actuators can be used in many explosion-proof or hazardous environments. All Baelz actuators can support extreme cold temperatures as low as -40 °C. Our electric actuator can be supplied with stainless steel hoods, internal heaters, and thermostats.

We maintain high inventory levels within the United States to ensure quick delivery of products to our North American customers. As part of our service portfolio, we also provide on-site and off-site equipment support. Our experts can help you select the best actuator solution for your industrial application. We possess unmatched expertise in valve technology, and our actuator solutions all come with a full factory warranty.

Please don’t hesitate to contact us to find out more about our actuator product line and related services.

Looking for Technical Data and Resources?

Browse our collection of eBooks, brochures, and data sheets.

Get access now!

Please complete the form below to access the data sheets on this page. Click here to return home.