The production process for textiles consumes a large amount of energy. As such, manufacturers in the textile industry are always looking for effective energy-saving measures to help cut down on costs. Since the 1950s, Baelz NA has been a partner in the textile industry, working closely with fabricators such as Artos, Babcock, and Brückner. We not only serve the industry as an OEM in textile machine construction, but we can also retrofit existing factories with our energy-saving technologies.

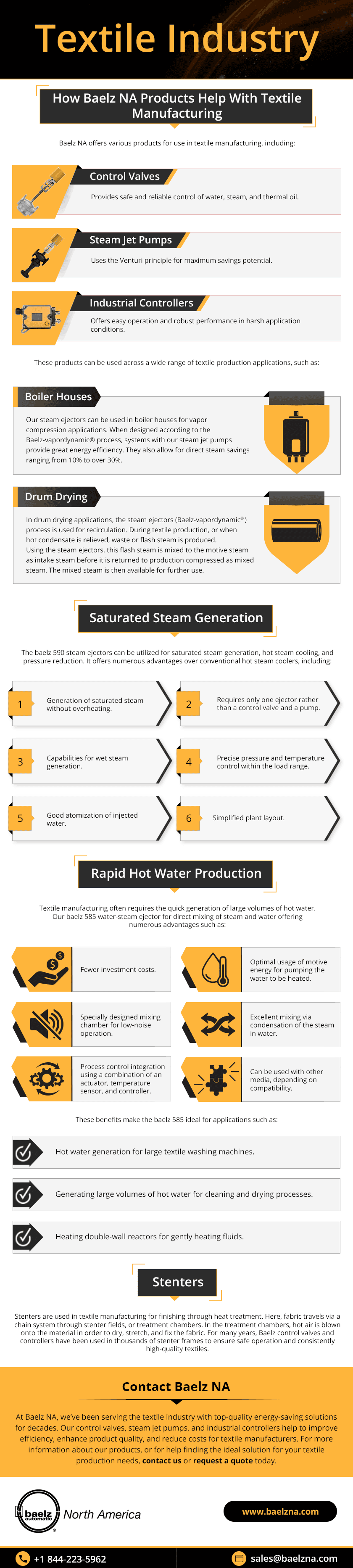

How Baelz NA Products Help With Textile Manufacturing

Baelz NA offers various products for use in textile manufacturing, including:

- Control valves: Provides safe and reliable control of water, steam, and thermal oil

- Steam jet pumps: Uses the Venturi principle for maximum savings potential

- Industrial controllers: Offers easy operation and robust performance in harsh application conditions

These products can be used across a wide range of textile production applications, such as:

Boiler Houses

Our steam jet pumps can be used in boiler houses for vapor compression applications. When designed according to the Baelz-vapordynamic® process, systems with our steam jet pumps provide great energy efficiency. They also allow for direct steam savings ranging from 10% to over 30%. To illustrate the effectiveness of our steam jet pumps, check out these case studies:

- Textile factory near Valencia/Spain. Using our steam jet pump, we were able to close a 15m3 large, previously open condensate collecting vessel.

- Large textile factory near Izmir/Turkey. We optimized a large plant with multiple steam boilers using our steam jet pumps. A small condensate collecting vessel with 100I is sufficient in this system.

Drum Drying

In drum drying applications, the Baelz-vapordynamic® process is used for recirculation. During textile production, or when hot condensate is relieved, waste or flash steam is produced. Using the steam jet pump, this flash steam is admixed to the motive steam as intake steam before it is returned to production compressed as mixed steam. The mixed steam is then available for further use.

The mixture of intake steam with motive steam results in lower steam consumption at a high steam velocity, as well as a thinner condensate film within the cylinder. This leads to improved heat throughput for faster drying.

Our steam jet pump uses a suction effect to circulate the steam in the cylinder, resulting in stable and more even temperature distribution over the length of the drums. This also creates a more uniform drying process and enhances the quality of the end product. Steam recovery leads to less condensate compared to conventional systems, reducing the risk of condensate trap failure for improved system availability.

Saturated Steam Generation

The Baelz 590 steam jet pump can be utilized for saturated steam generation, hot steam cooling, and pressure reduction. It offers numerous advantages over conventional hot steam coolers, including:

- Generation of saturated steam without overheating

- Requires only one valve rather than a control valve and fixed-nozzle jet pump

- Capabilities for wet steam generation

- Precise pressure and temperature control within the load range

- Good atomization of injected water

- Simplified plant layout

Rapid Hot Water Production

Textile manufacturing often requires the quick generation of large volumes of hot water. Our Baelz 585 steam-water mixer features a special design that is ideally suited for processes necessitating the rapid production of hot water. It works by effectively mixing steam and water, offering numerous advantages such as:

- Fewer investment costs

- Optimal usage of motive energy for pumping the water to be heated

- Specially designed mixing chamber for low-noise operation

- Excellent mixing via condensation of the steam in water

- Process control integration using a combination of an actuator, temperature sensor, and controller

- Can be used with other media, depending on compatibility

These benefits make the Baelz 585 ideal for applications such as:

- Hot water generation for large textile washing machines

- Generating large volumes of hot water for cleaning and drying processes

- Heating double-wall reactors for gently heating fluids

Stenters

Stenters are used in textile manufacturing for finishing through heat treatment. Here, fabric travels via a chain system through stenter fields, or treatment chambers. In the treatment chambers, hot air is blown onto the material in order to dry, stretch, and fix the fabric. For many years, Baelz control valves and controllers have been used in thousands of stenter frames to ensure safe operation and consistently high-quality textiles.

Contact Baelz NA

At Baelz NA, we’ve been serving the textile industry with top-quality energy-saving solutions for decades. Our control valves, steam jet pumps, and industrial controllers help to improve efficiency, enhance product quality, and reduce costs for textile manufacturers. For more information about our products, or for help finding the ideal solution for your textile production needs, contact us or request a quote today.

Looking for Technical Data and Resources?

Browse our collection of eBooks, brochures, and data sheets.

Get access now!

Please complete the form below to access the data sheets on this page. Click here to return home.