Recapturing Waste Steam Heat Energy

Industrial processes can waste a lot of heat energy, but there are many components and systems available to help your facility recoup and reuse that energy. Waste heat energy includes heat transferred from hot surfaces or direct heating processes, as well as heated combustion gases that get released outside the facility. Some studies estimate that as much as 20% to 50% of total industrial energy input is lost as waste heat.

Integrating heat recovery technologies into industrial processes can reduce that number, shrinking your facility’s footprint and reducing energy costs. As a company committed to innovation, Baelz NA helps industrial facilities reduce energy losses through a wide array of controls and components.

Waste Heat Recovery In Industrial Applications

Waste heat recovery is a system through which organizations can recover heat energy to reuse as heating or even to power building systems, getting more energy and production out of every unit of energy consumed. Some approaches to waste heat recovery include:

- Preheating combustion air

- Preheating furnace loads

- Generating on-site electricity

- Absorption cooling processes

- General space heating and climate control

Using one or all of these strategies can significantly improve operations and reduce overhead.

Products for Recapturing Waste Steam Heat Energy

Baelz NA partners with corporations across major industrial sectors to provide precise and energy-efficient production systems. Our waste steam heat energy recapture systems offer the following:

- Excellent return on investment through energy recapture (and long-term availability of spare parts) for an extended system lifespan

- Low-maintenance and dependable operation

- A wide selection of products and material options with versatile combinations

- Short delivery windows for standard and custom parts to minimize facility disruption

- Low leakage rates of Class IV or VI for standard parts and soft seal plug

- DIN and ANSI-compliant product variations

Our components used in waste heat recovery systems include:

Control Valves

Our 2-way and 3-way control valves can be used to control the movement of fluids, such as thermal oil and water, as well as steam and other gases. Our valve options include:

- ANSI 300 Class sizes 1 inch through 6 inch.

- DN15 to DN 300 sizes with pressure ratings of PN 16 or PN 40

Additionally, we leverage decades of experience with thermotechnical systems to help our customers select the best control valves for reliable long-term use in the given application.

Actuators

Our electric actuators feature multiple operating options, built-in failsafes, and variable output options of 1000-15000 N. They also boast automatic stroke range detection for more efficient control. Our pneumatic actuators possess a lightweight aluminum construction, fast reaction times, and force of 1N- 31N with I/P digital positioners. These actuators benefit from a modular design concept that offers easy positioning and regulation.

Ejectors

Reduce energy costs and effectively recapture waste heat with systems that use our DN20 to DN250 ejectors. These ejectors offer a simplified design with low-maintenance construction, few moving parts, and reliable hydraulic stability. Facilities don’t need to buy additional fittings when using our ejectors, further reducing waste. Moreover, our ejectors can handle lower return temperatures than other models on the market.

Temperature Controllers

Industrial facilities and buildings can automate process equipment temperatures through our control technology software package. This software has a modular structure, so users can customize it to suit the needs of different facilities and processes. Additionally, it can automatically regulate temperatures without constant manual monitoring or adjustments.

Control Loop Technology

Baelz control loop technology controllers use in-house developed hardware and software systems that use automation to monitor and adjust temperatures. They integrate with process control and building control systems to refine energy consumption and more efficiently consume, convert, or generate energy, depending on your needs.

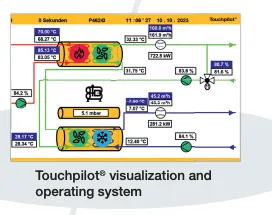

Additionally, Baelz NA control loop technology controllers can incorporate Touchpilot® touchscreen hardware.

Contact Baelz NA for Waste Heat Recovery Solutions

Implementing smarter process technologies and hardware such as actuators, ejectors, and valves can help industrial facilities reduce waste steam heat energy. Controlling losses from the outset is a clear and measurable way to reduce energy consumption and meet your efficiency goals. At Baelz North America, we design hardware and software solutions that power smarter operations. Our energy-saving solutions ensure high product quality through our extensive in-house design capabilities and cost savings through lower maintenance, longer-lasting parts, and greater energy efficiency. They can also contribute to overall sustainability through lower energy loss and future-proof designs.

Contact us today to learn more about how our fluid system components and automation solutions can help you reduce or recapture waste steam heat energy. You can also request a quote to start your order of our components or systems.