Wood Industry

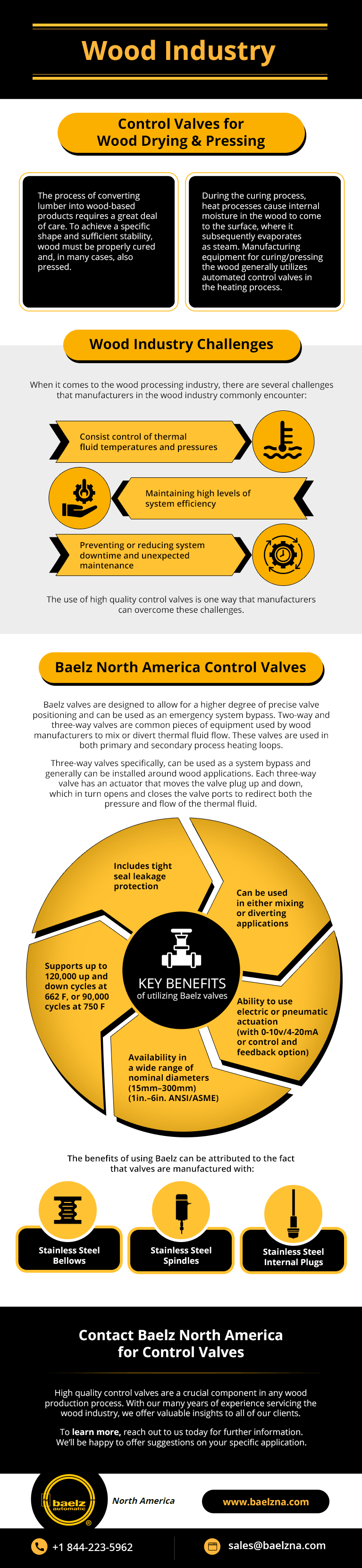

Control Valves for Wood Drying & Pressing

The process of converting lumber into wood-based products requires a great deal of care. To achieve a specific shape and sufficient stability, wood must be properly cured and, in many cases, also pressed.

During the curing process, heat processes cause internal moisture in the wood to come to the surface, where it subsequently evaporates as steam. Manufacturing equipment for curing/pressing the wood generally utilizes automated control valves in the heating process.

Wood Industry Challenges

When it comes to the wood processing industry, there are several challenges that manufacturers in the wood industry commonly encounter:

- Consist control of thermal fluid temperatures and pressures

- Maintaining high levels of system efficiency

- Preventing or reducing system downtime and unexpected maintenance

The use of high quality control valves is one way that manufacturers can overcome these challenges.

Baelz North America Control Valves

Baelz valves are designed to allow for a higher degree of precise valve positioning and can be used as an emergency system bypass. Two-way and three-way valves are common pieces of equipment used by wood manufacturers to mix or divert thermal fluid flow. These valves are used in both primary and secondary process heating loops.

Three-way valves specifically, can be used as a system bypass and generally can be installed around wood applications. Each three-way valve has an actuator that moves the valve plug up and down, which in turn opens and closes the valve ports to redirect both the pressure and flow of the thermal fluid.

Key benefits of utilizing Baelz valves:

- Can be used in either mixing or diverting applications

- Ability to use electric or pneumatic actuation (with 0-10v/4-20mA or control and feedback option)

- Availability in a wide range of nominal diameters (15mm–300mm)

- Supports up to 120,000 up and down cycles at 662 F, or 90,000 cycles at 750 F

- Includes tight seal leakage protection

The benefits of using Baelz can be attributed to the fact that valves are manufactured with stainless steel bellows, spindles, and internal plugs.

Contact Baelz North America for Control Valves

High quality control valves are a crucial component in any wood production process.

With our many years of experience servicing the wood industry, we offer valuable insights to all of our clients. For example, we recommend that all wood production facilities maintain an inventory of valve spares (at least 10%) to prevent unnecessary downtime. Baelz NA maintains stock levels in the U.S. that allow us to provide customers with shorter lead times.

To learn more, reach out to us today for further information. We’ll be happy to offer suggestions on your specific application.