Thermal Oil Application

Thermal oils are fluids that circulate within a thermal fluid system to transfer thermal energy, gradually cooling or heating the system or other oils to control process temperatures. Thermal oil systems are a suitable alternative to hot water- or steam-driven systems for heat transfer, with each system having its own optimal uses. Numerous applications use thermal oils, and so diverse sectors such as military, marine, wood, chemical, automotive, aerospace, and food and beverage employ thermal fluid systems for machine cooling, process heating, metalworking, and much more.

Since 1896, Baelz North America has developed a reputation as a trusted partner for heat transfer system solutions. We specialize in energy-saving, low-maintenance systems that optimize the affordable supply of heat and cooling. Learn more about our thermal fluid systems, how they work, and the benefits they offer to industrial applications.

Thermal Fluid Systems

The chemical makeup of thermal oils and heat transfer fluids varies, and they may consist of synthetic or non-synthetic materials. Polyglycol and water-glycol fluids, ester and diester compounds, and silicone-based oils and greases are examples of synthetic products. They are made from organic and inorganic alkaline compounds, and their concentrations can range from 3 to 10% when applied in diluted form. Non-synthetic products often contain water and mineral or petroleum oils.

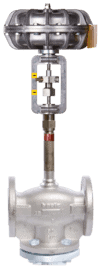

To generate heat, a thermal oil heater will fire through a helical-shaped coil, and the combustion creates hot byproducts. As a pump recirculates the thermal oil and it passes through the hot helical coil, the direct contact with this heating element warms the oil, which, in turn, helps heat processes within an application as it passes. Thermal fluid systems utilize a continuous process, so the fluid will ultimately return to the heating system from the process heat user.

This is ideal for industrial plants and other facilities that have continuous operations, as they require systems that function unceasingly for reliable thermal control. Thermal oil works particularly well as a heat transfer medium for cooling other oils or for indirectly heating bigger industrial applications. They also have applications involving compressors, piston pumps, gears, drives, engine components, and processing equipment.

Benefits

Thermal fluid systems offer numerous advantages for heat transfer applications. Users can benefit from outdoor installation capabilities and minimal maintenance needs by using thermal oils or fluids. Compared to water boilers, thermal oil systems are often more affordable to run and maintain. Benefits of adopting a thermal oil heating system include:

- Prevention properties. Specialty varieties of thermal oil have the capability of either preventing or reducing the risk of corrosion, oxidation, scale, and microbe growth. This can offer systems better operational protection and improves the life span of system components.

- Low pressures resulting in high heat. Typical thermal oil-driven systems handle temperatures between 32° F and 650° F, with a constant pressure ranging from 50 to 75 PSIG. In contrast, a hot water system runs at temperatures between 32° F to 250° F, and a steam-driven system can only heat to temperatures between 250° F and 350° F at design pressures of 150 PSIG.

- Reduced maintenance. Closed-loop, simple-circuit thermal fluid systems do not call for fluid makeup. Compared to a steam boiler, for which maintenance is more complex and recurrent, the maintenance requirements for thermal fluid systems are lower because of the circuit’s simplicity.

Partner With Baelz NA

At Baelz NA, our team is committed to high product quality and reductions in energy consumption to provide you with lasting, cost-effective heat transfer systems using thermal oil, water, or steam. To best serve you with versatile solutions, we can customize our products to meet your individual specifications. The next time you consider updating your facility’s process heating equipment, consider a thermal fluid system by Baelz NA.

Contact us for more information on our equipment and capabilities, or request a quote today to begin your project.