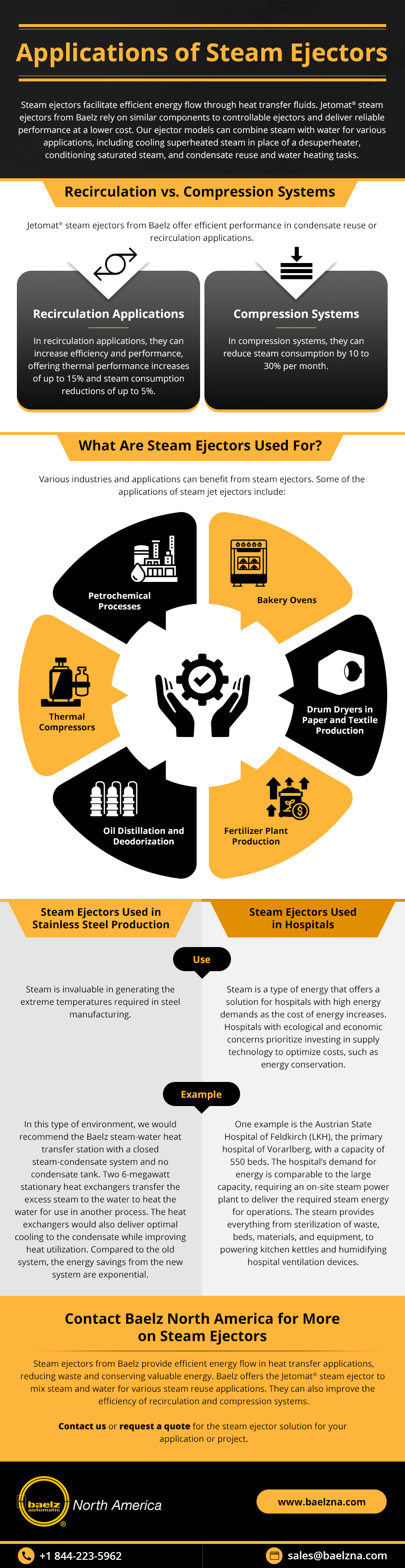

Applications of Steam Ejectors

Steam ejectors facilitate efficient energy flow through heat transfer fluids. Jetomat® steam ejectors from Baelz rely on similar components to controllable ejectors and deliver reliable performance at a lower cost. Our ejector models can combine steam with water for various applications, including cooling superheated steam in place of a desuperheater, conditioning saturated steam, and condensate reuse and water heating tasks.

Recirculation vs. Compression Systems

Jetomat® steam ejectors from Baelz offer efficient performance in condensate reuse or recirculation applications. In compression systems, they can reduce steam consumption by 10 to 30% per month. In recirculation applications, they can increase efficiency and performance, offering thermal performance increases of up to 15% and steam consumption reductions of up to 5%.

What Are Steam Ejectors Used For?

What is a steam ejector used for? Various industries and applications can benefit from steam ejectors. Some of the applications of steam jet ejectors include:

- Bakery ovens

- Drum dryers in paper and textile production

- Fertilizer plant production

- Oil distillation and deodorization

- Thermal compressors

- Petrochemical processes

We will explore in-depth specific applications that can improve efficiency and performance by implementing Baelz steam ejectors.

Steam Ejectors Used in Stainless Steel Production

International stainless steel production companies consume vast amounts of energy during processes like steam generation. Steam is invaluable in generating the extreme temperatures required in steel manufacturing. In the past, steam-water transfer stations would route high-temperature condensate to open condensate tanks, resulting in flash steam escaping into the air from the evaporation lines. The process resulted in massive energy loss, corrosion from the atmospheric oxygen in the condensate lines, material wear, excess noise, and steam water hammers.

In this type of environment, we would recommend the Baelz steam-water heat transfer station with a closed steam-condensate system and no condensate tank. Two 6-megawatt stationary heat exchangers transfer the excess steam to the water to heat the water for use in another process. The heat exchangers would also deliver optimal cooling to the condensate while improving heat utilization. Compared to the old system, the energy savings from the new system are exponential.

Steam generation comes at a significant cost, so steam should be used economically to avoid a surplus. Implementing Baelz steam-water heat transfer stations can provide considerable energy savings due to its closed steam condensate system, preventing the waste of excess steam. The energy from the steam is saved and converted to hot water for use in other processes. Investing in a closed steam condensate system overcomes the challenges of open systems and steam hammers to provide energy and financial savings quickly.

Steam Ejectors Used in Hospitals

Steam is a type of energy that offers a solution for hospitals with high energy demands as the cost of energy increases. Hospitals with ecological and economic concerns prioritize investing in supply technology to optimize costs, such as energy conservation. One example is the Austrian State Hospital of Feldkirch (LKH), the primary hospital of Vorarlberg, with a capacity of 550 beds. The hospital’s demand for energy is comparable to the large capacity, requiring an on-site steam power plant to deliver the required steam energy for operations. The steam provides everything from sterilization of waste, beds, materials, and equipment, to powering kitchen kettles and humidifying hospital ventilation devices.

Previously, excess steam was often released into the surrounding environment. However, a Baelz steam heat transfer station is now utilized to capture this steam, which is then used to produce heating water at a temperature of 80°C to heat the clinic. The heating water is stored in a large buffer tank, which functions as a hydraulic separator, and can be supplied to the heating network on an as-needed basis.

Contact Baelz North America for More on Steam Ejectors

Steam ejectors from Baelz provide efficient energy flow in heat transfer applications, reducing waste and conserving valuable energy. Baelz offers the Jetomat® steam ejector to mix steam and water for various steam reuse applications. They can also improve the efficiency of recirculation and compression systems. Our steam ejectors offer performance in various industries, including stainless steel production and hospitals, to efficiently and cost-effectively reuse steam energy.

Baelz NA provides the quality and service of a brand with over 125 years of experience with local representation to improve communication and lead times. Contact us or request a quote for the steam ejector solution for your application or project.