Ejectors can be used wherever the main pump generates sufficient differential pressure. According to VDI 2067, conventional circulation pumps have a lifetime of 10 years, whereas ejectors have a lifetime of 20 years. Ejectors are frequently used in the energy sector in heating, hot water, and ventilation system applications. Baelz ejectors can be utilized with pneumatic or electric actuator options.

What Is an Ejector?

Ejectors are static devices that use the high pressure of a motive liquid or gas to compress and entrain a low-pressure flare gas to an intermediate discharge pressure. They are mounted to the pipeline and can be produced from various materials to suit different process conditions.

Ejectors are an energy-efficient process solution that ensures an efficient flow of energy through heat transfer fluids. These devices will provide distribution and the exact amount of heated water over dozens of circuits without the use of a pump. Based on Bernoulli’s equation and the Venturi principle, the kinetic energy of water is conserved and not wasted like a typical 3-way valve application.

Ejectors Available From Baelz NA

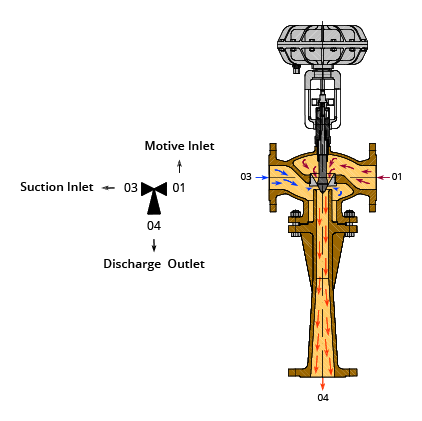

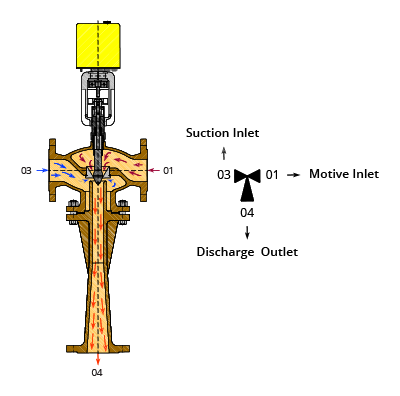

The types of ejectors we offer at Baelz NA include controllable nozzle steam and water ejectors. A controllable nozzle ejector is a 3-way control valve with intrinsic suction power. These ejectors have a motive inlet, suction inlet, and discharge outlet on the bottom.

Steam Ejectors

Steam jet ejectors are the largest-sized vacuum-producing ejectors currently available for highly demanding applications. The ejectors contain few moving parts, making them nearly maintenance-free. Baelz NA fabricates steam jet ejectors from various materials for use in any industry that requires vacuum pressure.

Baelz Jetomat® steam ejectors rely on similar components and operating principles as traditional controllable ejectors, reducing energy consumption and delivering reliable performance. Our selection of Jetomat® ejectors can mix steam and water directly for applications such as:

- Water heating

- Saturated steam conditioning

- Condensate reuse

- Superheated steam cooling

- Recirculation ejectors

Jetomat® baelz 590

The Jetomat® baelz 590 is a high-quality steam/steam ejector built to recirculate and compress exhaust vapor in industrial and commercial systems. With a body constructed from spheroid ductile iron (5.3103) and cast steel (1.0619), its safe operating temperature ranges from -10° C to 240° C, or as high as 350° C with the supplemental cooling tube. For nominal pressure, it’s rated for PN 16/40. This product has a flanged connection and nominal diameter options of DN 15-250.

Water Ejectors

To distribute heating water to secondary circuits, Baelz Jetomat® water ejectors use controlled ejector technology in place of pumps and control valves for each circuit. Using our ejectors can deliver long-term cost and energy savings in ventilation and heating systems, with many systems operating for 30 years or more. Our water ejectors can replace any water control valve in systems where the main pump generates adequate differential pressure.

Jetomat® baelz 480

Recirculate and mix liquids with the Jetomat® baelz 480. This controllable ejector features flanged connections and a body consisting of cast steel (1.0619) and spheroid ductile iron (5.3103). It’s available in nominal diameters of DN 15-300 and can handle PN 16/40 nominal pressure. Without the cooling tube, the baelz 480 can withstand temperatures ranging from -10° C to 240° C, but the cooling tube increases that temperature range up to 350° C.

How Do Ejectors Work?

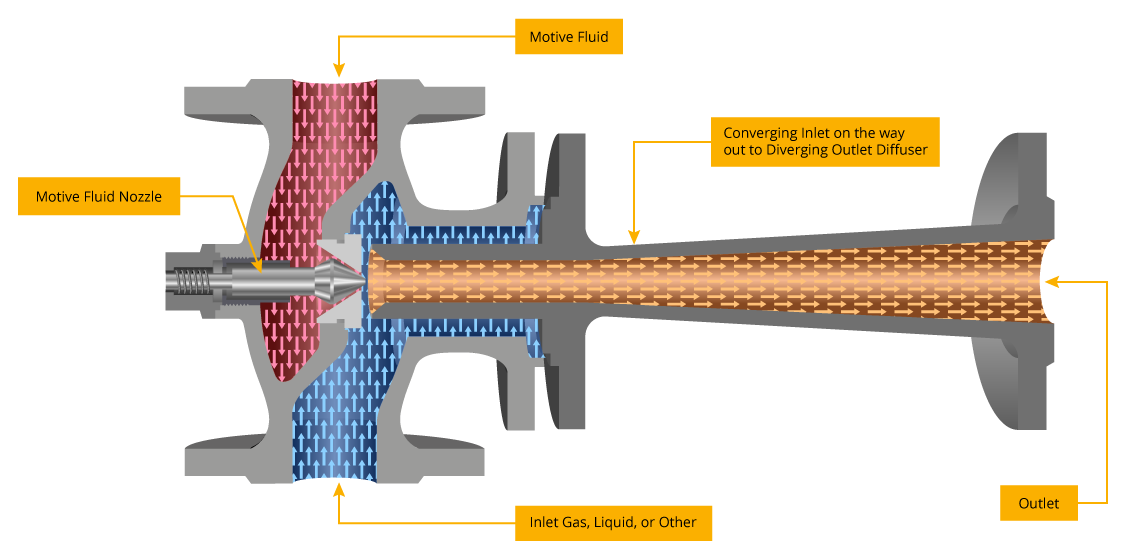

Ejectors work on Bernoulli’s principle, which states that fluid velocity increases as pressure decreases. The opposite is also true — as fluid velocity decreases, its pressure increases. Ejectors accelerate a motive, or high-pressure, stream through the nozzle, generating velocity from the motive’s pressure. They create the highest velocity around the nozzle tip, resulting in a low-pressure region called the ejector’s suction chamber.

The region where the pressure is lower than that of the suction fluid connects to the ejector’s suction branch or side inlet. The suction branch carries the fluid into the ejector body, transferring the two fluid streams through the ejector’s diffuser, where they decrease in velocity and increase in pressure due to the diverging geometry. As the suction stream pressure compresses and increases, the pressure of the motive stream decreases, transferring a portion of its energy to the suction stream. As a result, the pressure that the ejector discharges falls between the motive and suction pressures.

Operating Profile of Ejectors

When you’re considering an ejector for your application, it’s important to understand how they operate and for which circumstances they’re best suited. Ejectors function based on mass rather than volume displacement, making them ideally compatible with low absolute pressure applications, high vacuum tasks, and gases with minimal molecular weight.

Achieving supersonic velocity, a motive fluid jet will entrain the inlet stream so the fluid flows combine and mix effectively. Next, within the diffuser’s throat, a stationary shock wave will develop, dramatically increasing the absolute pressure. The pressure also increases as, inversely, the flow rate slows along the discharge cone.

Steam, which is a particularly common motive fluid, can reach between 80 and 400 PSIG, or 6 to 28 bar abs., respectively. You can also utilize alternate motive fluids if steam isn’t compatible with your materials or product. Depending on your system’s requirements, you can use a single ejector to achieve a 27 in. Hg vacuum, which is approximately 76 mm HgA, or you can install multiple ejectors in a series to generate a deeper vacuum.

Applications of Ejectors

Steam and water ejectors have applications throughout diverse industries to precisely mix, recirculate, compress, and distribute fluids.

Chemical Industry

Ejectors are key devices in creating reactor vacuums that enable manufacturing and processing centers to produce chemical reactions at lower temperatures while expending less energy. Reactor vacuums help prevent unwanted chemical reactions, thermal degradation, and polymerization. Ejectors also support material concentration in liquid form in evaporator vacuums. With the help of a condenser to boil off the water during this process, generating a vacuum reduces energy consumption and the associated costs while protecting temperature-sensitive materials.

Oil and Gas Industry

This market commonly uses ejectors to facilitate the vacuum distillation process. This technique allows the oil and gas industry to separate multiple volatile materials that have dissimilar boiling points by putting a product in a vacuum for condensing.

Food and Beverage Industry

Processing centers within the food and beverage industry can use ejectors for several processes. For example, ejectors allow edible oil manufacturers to create vacuum conditions for eliminating contaminants and unwanted coloring from the product through a bleaching and deodorizing process. Companies can dry solid goods faster and at lower temperatures within a vacuum, which is especially useful for products that can sustain heat damage or end products that require low concentrations of moisture. They can also concentrate sugar syrup in sugar vacuum pans, using evaporator vacuum conditions to transform the juice into sugar crystals.

Electric Power Industry

To assist with condenser exhausting in the power generation sector, ejectors play a part in maximizing a turbine’s steam expansion and maintaining the appropriate vacuum conditions within the condenser. The purpose of the vacuum in the process is to eliminate any air leaking into the turbine condenser.

Source Ejectors From Baelz NA

Ejectors are simple devices mounted to fluid system pipelines that compress and transport suction fluid in motive fluid systems. They are an energy-efficient, low-maintenance solution with few moving parts, minimizing maintenance needs. Their efficient operation and longevity can result in a significantly lower cost of ownership over the device’s lifespan compared to circulation pumps.

Baelz NA produces and supplies various ejectors, including steam ejectors and water ejectors. Our Jetomat® steam ejectors can be used to cool superheated steam, heat water, reuse condensate, and condition saturated steam. Our water ejectors can replace pumps and control valves in secondary circuit systems, reducing energy consumption. Contact us or request a quote to speak with a specialist about the ideal ejector solution for your application.

Looking for Technical Data and Resources?

Browse our collection of eBooks, brochures, and data sheets.

Get access now!

Please complete the form below to access the data sheets on this page. Click here to return home.